Improving warehouse efficiency and reducing costs are key goals for any business dealing with inventory management. A well-organized warehouse not only enhances productivity but also ensures timely delivery of products to customers. Here are five effective ways to boost your warehouse efficiency and cut costs.

1. Optimize Your Layout for Warehouse Efficiency

The layout of your warehouse plays a crucial role in determining how efficiently operations are carried out. An optimized layout can minimize travel time, reduce bottlenecks, and improve overall workflow.

Tips to Optimize Your Warehouse Layout

A. Implement ABC Analysis:

ABC analysis categorizes inventory into three groups:

- A-items: High-value products with a low frequency of sales.

- B-items: Moderate-value products with moderate sales frequency.

- C-items: Low-value products with high sales frequency.

Place A-items closer to the storage area to minimize handling, while C-items can be stored further away.

B. Use Vertical Space:

Maximize your storage space by using vertical storage solutions like tall shelves and mezzanine floors. This can significantly increase the capacity without expanding the warehouse footprint.

C. Streamline Aisles and Paths:

Ensure that aisles are wide enough for easy movement of forklifts and pallet jacks. Clearly mark pathways to avoid confusion and ensure smooth traffic flow.

Example:

A local electronics distributor in Malaysia restructured their warehouse layout by grouping high-demand products closer to the shipping area. This reduced the time their staff spent picking and packing orders, leading to a 20% increase in productivity.

2. Invest in Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) is a software solution that helps in tracking inventory levels, managing orders, and optimizing warehouse operations. Implementing a WMS can lead to significant improvements in efficiency and cost savings.

Benefits of a WMS for warehouse efficiency

A. Real-Time Inventory Tracking:

With a WMS, you can track inventory levels in real-time, reducing the chances of overstocking or stockouts. This ensures that you have the right amount of stock at all times.

B. Improved Order Accuracy:

A WMS reduces human errors in order picking and packing, ensuring that customers receive the correct products.

C. Better Space Utilization:

By analyzing inventory data, a WMS can suggest the most efficient storage locations for different products.

Example:

A small e-commerce business in Malaysia implemented a WMS and saw a 30% reduction in order processing time. The system helped them manage their inventory more effectively, leading to fewer mistakes and happier customers.

3. Implement Automation

Automation can significantly enhance the efficiency by reducing manual labor and speeding up processes. There are various levels of automation that can be implemented depending on the size and budget of your warehouse.

Types of Warehouse Automation

A. Automated Storage and Retrieval Systems (AS/RS):

These systems use robotic technology to store and retrieve items from designated locations. This reduces the time spent on manual picking and minimizes errors.

B. Conveyor Systems:

Conveyor systems can transport goods from one area to another, reducing the need for manual handling and speeding up the process.

C. Automated Guided Vehicles (AGVs):

AGVs are used to transport goods within the warehouse without human intervention. They can follow pre-defined paths and are ideal for repetitive tasks.

Example:

A large distribution center in Malaysia implemented conveyor systems and AGVs, which reduced their manual handling by 50%. This not only increased their operational efficiency but also lowered labor costs.

4. Train and Empower Your Staff

Well-trained staff are essential for the smooth operation of a warehouse. Investing in employee training can lead to improved productivity, better morale, and reduced turnover.

Training Tips

A. Regular Training Sessions:

Conduct regular training sessions to keep your staff updated on the latest practices and technologies. This can include safety training, equipment handling, and software usage.

B. Cross-Training:

Cross-training employees to perform multiple roles can provide flexibility in managing workloads and ensure that operations continue smoothly even when some staff members are absent.

C. Empowerment:

Encourage employees to suggest improvements and take ownership of their tasks. This can lead to innovative solutions and a more motivated workforce.

Example:

A mid-sized warehouse in Malaysia started regular training sessions and empowered their staff to suggest improvements. This led to a more engaged workforce and a 15% increase in overall efficiency.

5. Monitor and Analyze Performance

Regular monitoring and analysis of warehouse performance can help identify areas for improvement and ensure that operations are running smoothly.

Key Performance Indicators (KPIs)

A. Order Accuracy Rate:

This KPI measures the percentage of orders correctly picked and packed. A high order accuracy rate indicates efficient warehouse operations.

B. Inventory Turnover:

This KPI measures how often inventory is sold and replaced over a period. A high inventory turnover indicates effective inventory management.

C. Average Order Processing Time:

This KPI measures the time taken to process an order from receipt to dispatch. Reducing this time can lead to faster delivery and improved customer satisfaction.

Example:

A logistics company in Malaysia started monitoring their KPIs and identified that their order processing time was longer than industry standards. By analyzing the data, they implemented changes that reduced their processing time by 25%.

Conclusion

Improving warehouse efficiency and reducing costs is essential for maintaining a competitive edge in today’s market. By optimizing your warehouse layout, investing in a WMS, implementing automation, training your staff, and monitoring performance, you can achieve significant improvements in your operations.

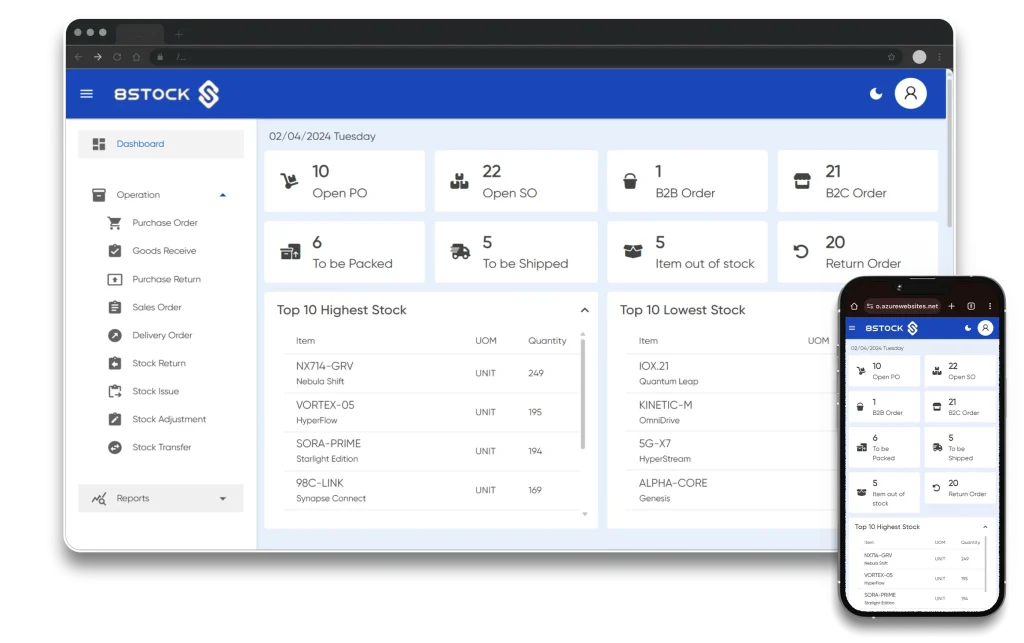

One such solution to consider is 8stock, a comprehensive WMS designed to streamline your operations and boost efficiency. By integrating 8stock into your warehouse management, you can leverage advanced features and real-time data to make informed decisions and enhance productivity.

Incorporating these strategies and tools into your warehouse operations will not only improve efficiency but also lead to significant cost savings, helping your business thrive in a competitive market.