When it comes to managing a warehouse, two key processes come into play: inbound and outbound. Understanding these terms and their roles can greatly improve the efficiency and effectiveness of any warehouse operation. In this article, we’ll break down these concepts, explore their importance, and show how they fit into the broader picture of warehouse management, including the role of third-party logistics (3PL). Plus, we’ll look at how a WMS like 8Stock can streamline these processes.

What is Inbound and Outbound Process in Warehouse Management??

Inbound process in warehouse

Inbound process refers to all activities related to receiving goods into the warehouse. Here’s a closer look at the steps involved:

- Receiving: This is the first step where goods arrive at the warehouse. They are unloaded from trucks or other transportation vehicles.

- Inspection and Quality Check: Once received, goods are inspected to ensure they match the purchase orders. This step helps identify any damages or discrepancies early on.

- Labeling: Goods are tagged with appropriate labels, such as barcodes or RFID tags, which helps in tracking and managing inventory.

- Putaway: This involves moving the goods to their designated storage locations within the warehouse.

- Inventory Updates: The warehouse inventory system is updated to reflect the newly received items, ensuring accurate inventory levels.

Real-World Example: Amazon’s Inbound Process

Amazon’s massive warehouses are a great example of efficient inbound processes. When goods arrive, they go through a detailed inspection process. Items are then labeled and stored using advanced robotics and software systems, ensuring quick and accurate putaway. This streamlined inbound process allows Amazon to maintain high levels of inventory accuracy and availability.

Outbound process in warehouse

Outbound process refers to the activities involved in shipping goods out of the warehouse. Here’s a breakdown of the steps:

- Order Processing: Customer orders are received and processed.

- Picking: Items are retrieved from their storage locations to fulfill the orders. This can be done manually or using automated systems.

- Packing: Items are packaged appropriately for shipping, including labeling and adding necessary documentation.

- Shipping: Orders are prepared for dispatch, including loading them onto transportation vehicles.

- Inventory Updates: The inventory system is updated to reflect the items that have been shipped out.

Real-World Example: Zara’s Outbound Process

Fashion retailer Zara is known for its efficient outbound process. When a customer places an order, it is quickly processed, and items are picked and packed efficiently. Zara’s sophisticated inventory management system ensures that stock levels are always up-to-date, enabling rapid fulfillment and shipping.

The Role of 3PL in WMS

Third-Party Logistics (3PL) providers play a crucial role in modern warehouse management. They offer outsourced logistics services, including inbound and outbound operations, allowing companies to focus on their core business.

Benefits of Using 3PL in WMS

- Expertise: 3PL providers have specialized knowledge and experience in logistics, ensuring efficient and cost-effective operations.

- Scalability: Businesses can scale their logistics operations up or down based on demand without significant capital investment.

- Technology: Many 3PL providers use advanced technology to manage warehouse operations, leading to improved accuracy and efficiency.

Real-World Example: Unilever’s Partnership with DHL

Unilever, a global consumer goods company, partners with DHL for its logistics needs. DHL handles both inbound and outbound operations for Unilever, leveraging its expertise and technology to ensure smooth and efficient logistics. This partnership allows Unilever to focus on its core business while benefiting from DHL’s logistics capabilities.

How 8Stock Enhances Warehouse Management

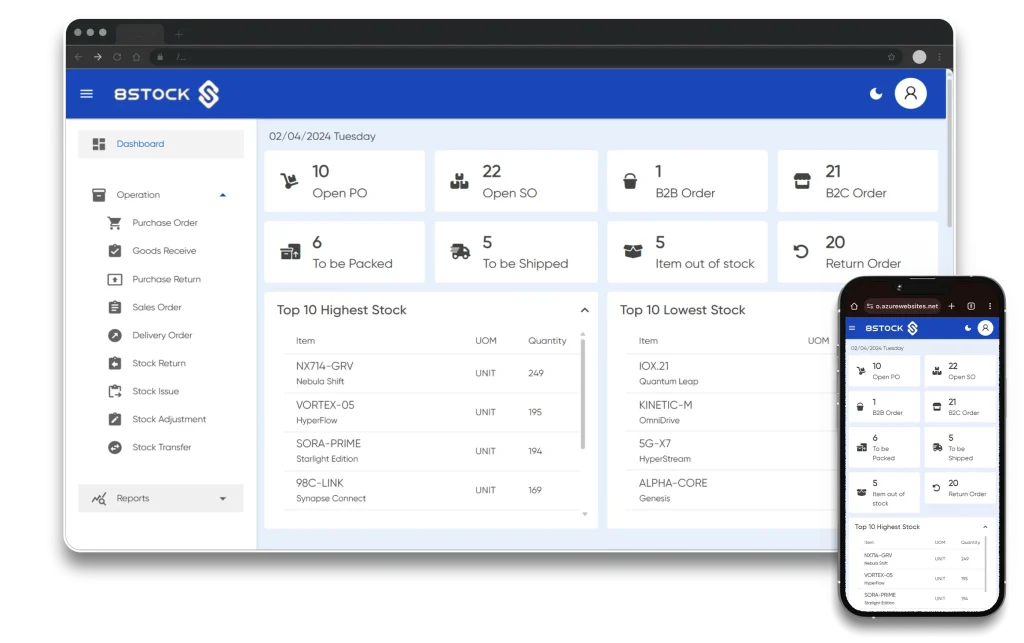

In the competitive world of warehouse management, having the right tools can make a significant difference. 8Stock is a powerful WMS designed to streamline both inbound and outbound processes, making your operations more efficient and effective.

Key Features of 8Stock

- Real-Time Inventory Tracking: 8Stock provides real-time updates on inventory levels, ensuring accuracy and reducing the risk of stockouts or overstocking.

- Automated Processes: The system automates key processes such as labeling, picking, and packing, reducing manual effort and minimizing errors.

- Integration with 3PL Providers: 8Stock seamlessly integrates with 3PL providers, allowing for smooth coordination of inbound and outbound logistics.

- User-Friendly Interface: Designed with simplicity in mind, 8Stock’s interface is easy to navigate, making it accessible to users of all skill levels.

Real-World Success Story: Local Retailer Boosts Efficiency with 8Stock

A local retailer recently implemented 8Stock to manage their warehouse operations. Since the implementation, they have seen a significant improvement in both inbound and outbound processes. Real-time inventory tracking has eliminated stock discrepancies, and automated processes have reduced manual labor by 30%. The integration with their 3PL provider has also streamlined their logistics, resulting in faster order fulfillment and happier customers.

Conclusion

Understanding the inbound and outbound processes in warehouse management is essential for running a smooth and efficient operation. Whether you’re handling these processes in-house or partnering with a 3PL provider, having the right tools and systems in place is crucial. 8Stock offers a comprehensive solution that can enhance both inbound and outbound logistics, making your warehouse operations more efficient and effective. By leveraging such technology, businesses can stay competitive and meet the demands of their customers with ease.