The truth is, managing a warehouse in today’s market is like trying to fix a plane while flying it. You have stock coming in, orders flying out, and a dozen things that could go wrong in between. With e-commerce in Malaysia and globally projected to hit massive numbers by 2026, relying on spreadsheets or memory just doesn’t cut it anymore.

If you are tired of losing inventory or dealing with slow fulfillment, a robust Warehouse Management System is what you need. It transforms chaotic inbound and outbound logistics into seamless operations. By leveraging automation, real-time tracking, and 3PL integration WMS, you can slash error rates and boost speed.

In this guide, we’re going to walk through exactly how to optimize your logistics flow. You’ll learn practical steps to streamline receiving, picking, and shipping without the headache. Let’s get your warehouse running like a well-oiled machine!

Understanding Inbound Logistics in WMS

Let’s start at the beginning: the receiving dock. If your inbound process is messy, your entire operation suffers—it is the classic “garbage in, garbage out” scenario. A modern Warehouse Management System acts as the gatekeeper, ensuring that what comes into your facility is accurate, recorded, and put away efficiently.

Step 1: Streamlined Receiving and ASN Processing

The days of manual clipboards are over. When a truck pulls up, your team needs to be ready. By using ASN processing WMS (Advance Shipping Notice), your system already knows what to expect before the driver even opens the door.

Your staff can use handheld scanners for Barcode RFID tracking to verify goods instantly against the purchase order. This immediate validation catches vendor errors right at the dock, not three weeks later when a customer complains.

Step 2: Quality Inspection and Cross-Docking

Once the goods are off the truck, speed is the name of the game. You don’t always need to store everything. If you have pending backorders, Cross-docking WMS features allow you to move items directly from the receiving dock to the outbound shipping area.

This bypasses storage entirely, reducing handling costs and getting products to customers faster. For items that do need storage, automated quality checks can flag damaged goods immediately, triggering a return to the vendor without clogging up your prime storage bins.

Step 3: Putaway Optimization

Where you put your stock matters as much as having it. If you put high-demand items on the top shelf in the back corner, you are killing your efficiency.

Putaway optimization algorithms in your WMS analyze item velocity (how fast it sells) and suggest the best bin location. It guides your forklift drivers to the optimal spot, ensuring that fast-movers are near the packing zone. This logic keeps your inventory optimization sharp and reduces travel time for your picking team later on.

Pro Tip: Don’t rely on driver memory for putaway. Force the system scan verification at the bin location. This ensures Real-time inventory tracking is 100% accurate from the moment the item hits the shelf.

Real-World Example: Amazon’s Inbound Process

Amazon’s massive warehouses are a great example of efficient inbound processes. When goods arrive, they go through a detailed inspection process. Items are then labeled and stored using advanced robotics and software systems, ensuring quick and accurate putaway. This streamlined inbound process allows Amazon to maintain high levels of inventory accuracy and availability.

Mastering Outbound Logistics with WMS Automation

Now, let’s talk about getting products out the door. This is where your customer creates their opinion of your brand. If you are slow or inaccurate here, they won’t come back. Mastering outbound logistics means reducing friction between the shelf and the shipping truck.

Step 1: Precision Picking Strategies

Picking usually eats up about 50% to 60% of total warehouse labor costs. Bringing in Warehouse automation 2026 tools can drastically cut this down. You shouldn’t have pickers walking 10km a day if they only need to walk 3km.

- Batch Picking: The system groups orders that need the same items, allowing a picker to grab multiple quantities of a SKU in one trip. This massively improves Batch picking efficiency.

- Zone Picking: Pickers stay in assigned zones, and the order container moves between them. This reduces congestion in the aisles.

- Voice-Directed Picking: Workers wear headsets that tell them where to go and what to grab. It keeps their hands free and eyes up, improving safety and speed.

Step 2: Packing and Shipping Validation

Once items reach the packing station, the WMS takes over quality control. A quick scan of the item and the order slip confirms a match. If it’s wrong, the system alerts the packer immediately, stopping an error from leaving the building.

This step is crucial for Order fulfillment accuracy. The system can also automatically generate shipping labels and determine the best box size to reduce waste.

Step 3: Rate Shopping and Logistics Integration

Shipping costs can kill your margins. A good WMS integrates with multiple carriers (like Pos Laju, DHL, or NinjaVan). It performs Shipping rate optimization in real-time, selecting the cheapest or fastest carrier based on the customer’s preference.

This automation removes the manual guesswork. You save money on every parcel, and the customer gets accurate tracking info instantly.

Step 4: Handling Returns (Reverse Logistics)

Returns are a pain, but they are part of the business. An efficient Reverse logistics WMS process is vital. When a return arrives, the system should quickly identify if it can be resold, needs repair, or should be discarded.

Fast processing here means you can get good inventory back online for sale immediately, rather than letting it pile up in a “dead corner” of the warehouse.

Real-World Example: Zara’s Outbound Process

Fashion retailer Zara is known for its efficient outbound process. When a customer places an order, it is quickly processed, and items are picked and packed efficiently. Zara’s sophisticated inventory management system ensures that stock levels are always up-to-date, enabling rapid fulfillment and shipping.

The Role of 3PL in WMS

Third-Party Logistics (3PL) providers play a crucial role in modern warehouse management. They offer outsourced logistics services, including inbound and outbound operations, allowing companies to focus on their core business.

Key Benefits of 3PL Integration in WMS

For many Malaysian business owners, running a full-scale warehouse operation in-house is too capital-intensive. This is where Third-Party Logistics (3PL) comes in. But here is the catch: you cannot just hand off your stock and hope for the best. You need deep integration.

Scalability Without the Overhead

When you sync your systems via 3PL integration WMS, you convert fixed costs (rent, labor) into variable costs. You pay for what you use.

During Peak season scaling—like the 11.11 or 12.12 sales—your 3PL can ramp up labor and space instantly. You don’t have to hire temporary staff or rent an overflow warehouse. Your WMS treats the 3PL’s inventory as if it were your own, giving you seamless control without the headache.

Access to Enterprise Technology

Most top-tier 3PLs invest millions in AI warehouse management and robotics. By integrating with them, you get access to Automated picking packing technology that might be too expensive to implement in your own facility.

This levels the playing field. Even a mid-sized SME can offer the same shipping speed and accuracy as a multinational corporation by leveraging the 3PL’s tech stack.

Risk Reduction and Visibility

One of the biggest fears with outsourcing is losing control. With a Supply chain visibility dashboard, that fear goes away.

A good WMS integration provides a two-way flow of data. You see exactly when an order is picked, packed, and shipped by the 3PL. If inventory runs low, you get alerts for Stockout prevention just as you would in your own warehouse. It ensures you maintain compliance and customer standards even when you aren’t physically touching the product.

Real-World Example: Unilever’s Partnership with DHL

Unilever, a global consumer goods company, partners with DHL for its logistics needs. DHL handles both inbound and outbound operations for Unilever, leveraging its expertise and technology to ensure smooth and efficient logistics. This partnership allows Unilever to focus on its core business while benefiting from DHL’s logistics capabilities.

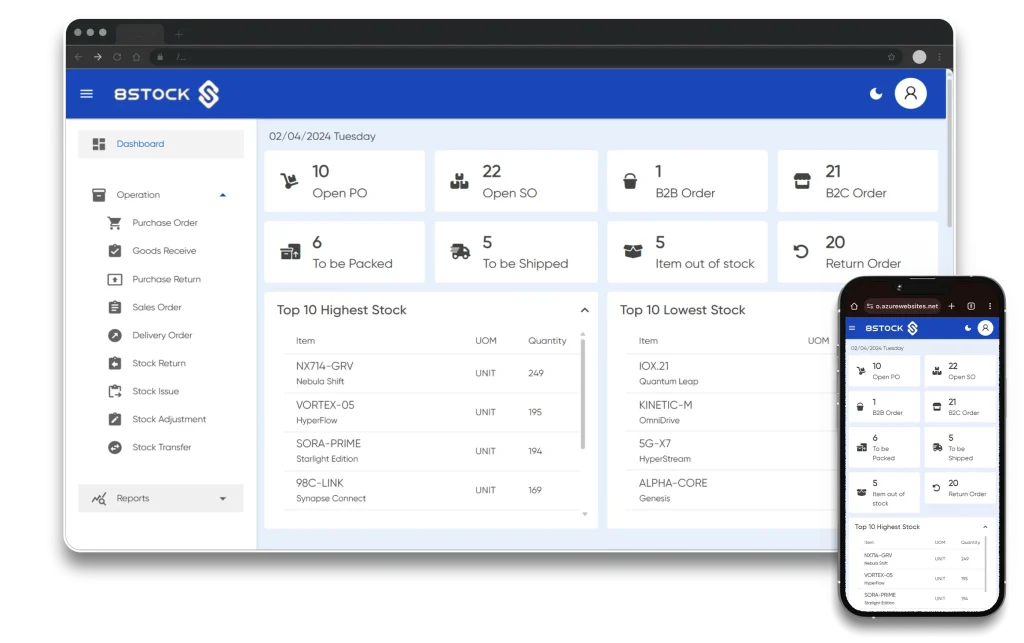

How 8Stock Enhances Warehouse Management

In the competitive world of warehouse management, having the right tools can make a significant difference. 8Stock is a powerful WMS designed to streamline both inbound and outbound processes, making your operations more efficient and effective.

Key Features of 8Stock

- Real-Time Inventory Tracking: 8Stock provides real-time updates on inventory levels, ensuring accuracy and reducing the risk of stockouts or overstocking.

- Automated Processes: The system automates key processes such as labeling, picking, and packing, reducing manual effort and minimizing errors.

- Integration with 3PL Providers: 8Stock seamlessly integrates with 3PL providers, allowing for smooth coordination of inbound and outbound logistics.

- User-Friendly Interface: Designed with simplicity in mind, 8Stock’s interface is easy to navigate, making it accessible to users of all skill levels.

Real-World Success Story: Local Retailer Boosts Efficiency with 8Stock

A local retailer recently implemented 8Stock to manage their warehouse operations. Since the implementation, they have seen a significant improvement in both inbound and outbound processes. Real-time inventory tracking has eliminated stock discrepancies, and automated processes have reduced manual labor by 30%. The integration with their 3PL provider has also streamlined their logistics, resulting in faster order fulfillment and happier customers.

Conclusion

Final Thoughts

Optimizing your logistics isn’t just about buying software; it’s about changing how you think about flow. WMS technology revolutionizes inbound and outbound logistics through automation, real-time tracking, and 3PL integration. These tools drive operational efficiency and scalability that manual processes simply cannot match in 2026.

Businesses that adopt these systems report faster fulfillment, lower costs, and happier customers. The supply chain is only getting more competitive. If you are still running your warehouse on paper and gut feeling, you are leaving money on the table.

Ready to see how a modern system can transform your operations? Request a 8Stock demo today and take the first step toward a smarter, faster warehouse.

Frequently Asked Questions (FAQs)

1. What is the difference between inbound and outbound logistics in WMS? Inbound logistics focuses on the processes of bringing goods into the warehouse, such as receiving, ASN processing WMS, and putaway. Outbound logistics deals with sending goods out, covering picking, packing, and shipping to the customer.

2. How does real-time tracking improve warehouse efficiency? Real-time inventory tracking ensures that the data in your system matches the physical stock on the shelves instantly. This prevents stockouts, enables accurate Demand forecasting WMS, and ensures Multi-channel inventory sync across platforms like Shopee and Lazada.

3. What are the top benefits of 3PL for WMS users? Integrating with a 3PL offers scalability without capital investment, access to advanced Warehouse automation 2026 technology, and significant Labor cost reduction warehouse. It allows you to handle peak seasons without expanding your own facility.

4. Can WMS automate picking and packing? Yes. WMS optimizes picking through strategies like Batch picking efficiency and Voice-directed picking. For packing, it validates items against orders to ensure Order fulfillment accuracy and can automatically generate shipping labels.

5. How to choose a WMS for 3PL integration? Look for a system with robust API capabilities, pre-built integrations for major carriers and marketplaces, and a user-friendly Warehouse analytics dashboard. Ensure it supports Multi-SKU management and provides Supply chain visibility across different locations.