Future Trends in Warehouse Management Systems: What to Expect

The world of warehouse management is evolving rapidly, driven by technological advancements and changing consumer demands. Staying ahead of these trends is crucial for maintaining efficiency and competitiveness. In this blog post, we’ll explore the future trends in warehouse management systems (WMS) and how they will shape the industry, including potential drawbacks to consider.

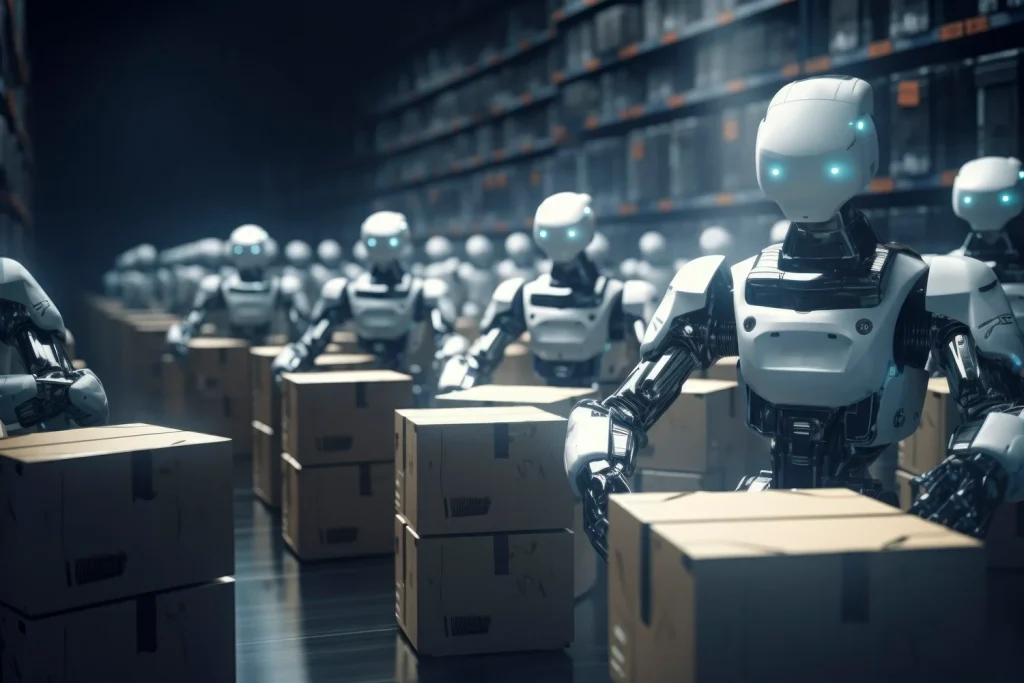

1. Automation and Robotics

Automation and robotics are transforming warehouses by reducing the reliance on manual labor and increasing operational efficiency. The future of WMS will see a surge in the adoption of autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and robotic picking systems.

- Increased Efficiency: Robots can work around the clock, ensuring continuous operations and faster order processing. This reduces lead times and improves customer satisfaction.

- Accuracy: Automation minimizes human error, leading to more accurate inventory management and order fulfillment.

- Safety: Robots can handle hazardous tasks, reducing the risk of workplace injuries.

Negative Effects:

- High Initial Investment: The cost of acquiring and implementing robotic systems can be substantial.

- Job Displacement: Increased automation may lead to job losses, affecting employee morale and leading to potential labor disputes.

- Maintenance and Downtime: Robots require regular maintenance and can be prone to technical issues, which can disrupt operations.

2. Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are set to revolutionize warehouse management by providing advanced data analytics and predictive insights.

- Demand Forecasting: AI can analyze historical data and market trends to predict future demand accurately, helping businesses maintain optimal inventory levels.

- Process Optimization: ML algorithms can identify inefficiencies in warehouse operations and suggest improvements, enhancing productivity.

- Personalization: AI-driven systems can customize order picking and packing processes based on customer preferences, improving the overall shopping experience.

Negative Effects:

- Complexity: Implementing AI and ML can be complex and requires skilled personnel to manage and interpret the data.

- Cost: Developing and maintaining AI systems can be expensive.

- Data Privacy: The use of AI involves extensive data collection, raising concerns about data privacy and security.

3. Internet of Things (IoT)

The Internet of Things (IoT) connects physical devices to the internet, allowing them to collect and share data. In the context of warehouse management, IoT devices can provide valuable insights into various aspects of operations.

- Real-Time Monitoring: IoT sensors can monitor environmental conditions, such as temperature and humidity, ensuring optimal storage conditions for sensitive products.

- Asset Tracking: IoT devices can track the location and status of assets in real-time, improving inventory accuracy and reducing loss or theft.

- Predictive Maintenance: IoT sensors can monitor the health of warehouse equipment, predicting maintenance needs before failures occur, minimizing downtime.

Negative Effects:

- Security Risks: IoT devices can be vulnerable to cyber-attacks, which can compromise sensitive data.

- Implementation Costs: Setting up IoT infrastructure can be costly and requires ongoing maintenance.

- Data Overload: The vast amount of data generated by IoT devices can be overwhelming and difficult to manage effectively.

4. Cloud-Based Solutions

Cloud-based WMS solutions are becoming increasingly popular due to their scalability, flexibility, and cost-effectiveness.

- Accessibility: Cloud-based systems can be accessed from anywhere, enabling remote management and collaboration.

- Scalability: Businesses can easily scale their WMS as they grow, without the need for significant upfront investments in hardware.

- Cost-Effectiveness: Cloud solutions reduce the need for on-premises infrastructure, lowering IT costs and maintenance requirements.

Negative Effects:

- Data Security: Storing data in the cloud can raise concerns about data security and privacy.

- Downtime and Reliability: Dependence on internet connectivity can lead to disruptions in case of network issues or outages.

- Vendor Lock-In: Businesses may face challenges if they decide to switch cloud providers, leading to potential compatibility and migration issues.

5. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies are making their way into warehouse management, offering innovative solutions for training, maintenance, and order picking.

- Training: AR and VR can provide immersive training experiences for new employees, helping them learn warehouse processes quickly and effectively.

- Maintenance: AR can overlay digital information onto physical equipment, guiding maintenance personnel through repair procedures.

- Order Picking: AR can assist workers in locating and picking items more efficiently by displaying navigation and product information in their field of view.

Negative Effects:

- High Costs: AR and VR technologies can be expensive to implement and maintain.

- Technical Challenges: These technologies require advanced hardware and software, which can be prone to technical issues.

- User Acceptance: Some employees may resist adopting new technologies, requiring additional training and support.

6. Blockchain Technology

Blockchain technology offers a secure and transparent way to manage and track transactions, making it a valuable tool for warehouse management.

- Traceability: Blockchain can provide an immutable record of product movements, enhancing traceability and accountability in the supply chain.

- Security: Blockchain’s decentralized nature makes it resistant to fraud and cyber-attacks, ensuring data integrity.

- Efficiency: Smart contracts can automate various processes, such as payment and shipment verification, reducing administrative overhead and speeding up transactions.

Negative Effects:

- Complexity and Cost: Implementing blockchain can be complex and expensive.

- Scalability Issues: Blockchain networks can face scalability challenges, affecting performance.

- Regulatory Concerns: The regulatory environment for blockchain is still evolving, leading to potential legal and compliance issues.

Conclusion

The future of warehouse management systems is exciting and full of potential. Automation, AI, IoT, cloud-based solutions, AR/VR, and blockchain are set to transform the way warehouses operate, making them more efficient, accurate, and adaptable. Though there are drawbacks, this will improve over time with technology still evolving for the betterment of businesses.

Staying ahead of these trends is crucial for businesses looking to maintain a competitive edge. 8Stock provides the tools and features to help you navigate these changes. Embracing these technologies will not only improve your current operations but also position your business for long-term success.

Explore how 8Stock can help you leverage these future trends and transform your warehouse operations. Contact us today for a demo and experience the benefits of a cutting-edge WMS firsthand.