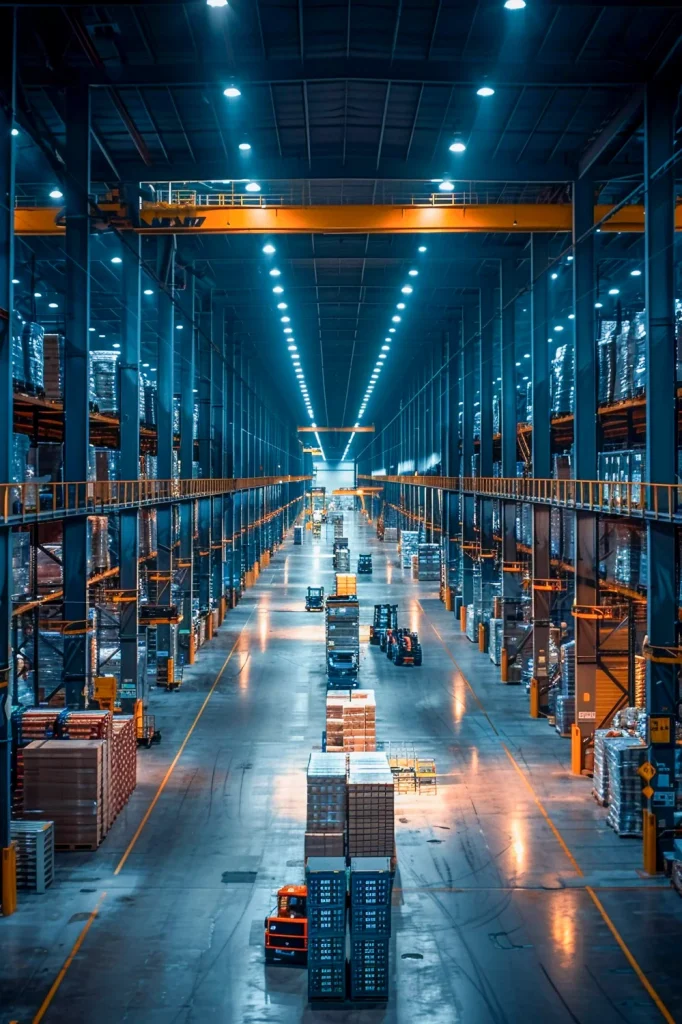

How WMS Transforms Inventory Management and Optimizes the Supply Chain

In today’s fast-paced business environment, efficient inventory management is crucial for the success of any company involved in the supply chain. Warehouse Management Systems (WMS) have become indispensable tools in achieving this efficiency. In this article, we will explore how WMS transforms inventory management and optimizes the supply chain, ensuring your business stays competitive.

What is a Warehouse Management System?

A Warehouse Management System (WMS) is a software application designed to support and optimize warehouse or distribution center management. It facilitates the management of daily planning, organizing, staffing, directing, and controlling the utilization of available resources. By integrating WMS into your operations, you can streamline your inventory management processes, reduce errors, and improve overall productivity.

The Role of WMS in Inventory Management

Inventory management is the backbone of any supply chain. Effective inventory management ensures that the right products are available at the right time and place, minimizing the risk of stockouts or overstocking. Here’s how WMS plays a crucial role:

1. Real-Time Inventory Tracking

One of the standout features is real-time inventory tracking. This capability allows businesses to have up-to-the-minute visibility of their stock levels, locations, and movements. Real-time data helps in making informed decisions, reducing the time and effort spent on manual inventory checks.

For instance, with real-time tracking, a business can quickly identify which products are running low and need restocking, or which items are overstocked and may need promotional efforts to clear space. This level of insight is invaluable for maintaining a balanced inventory.

2. Improved Accuracy

Manual inventory management is prone to errors, which can lead to significant losses. WMS automates data entry and reduces human errors, ensuring higher accuracy in inventory records. Accurate data helps in maintaining optimal stock levels, avoiding discrepancies, and enhancing customer satisfaction.

A common problem in manual inventory systems is the miscounting of stock, leading to either a surplus or a deficit. With system automation, barcodes are scanned to update inventory levels accurately, eliminating guesswork and reducing the likelihood of costly mistakes.

3. Enhanced Order Fulfillment

Order fulfillment is a critical aspect of inventory management and it streamlines the picking, packing, and shipping processes. Thus reducing the time taken to fulfill orders. Faster and more accurate order fulfillment leads to happier customers and repeat business.

For example, a WMS can optimize picking routes within the warehouse, ensuring that workers spend less time walking and more time picking items. It can also integrate with courier companies and shipping carriers to automate label printing and tracking, ensuring orders are shipped quickly and accurately.

4. Efficient Space Utilization

Optimize warehouse space by efficiently organizing inventory. It suggests the best storage locations for items based on their demand, size, and other factors. Efficient space utilization not only maximizes storage capacity but also reduces the time needed to locate and retrieve items.

Imagine this scenario where high-demand items are placed near the packing area to minimize retrieval time, while less frequently picked items are stored in more remote areas of the warehouse. Such strategic placement of inventory significantly boosts operational efficiency.

Optimizing the Supply Chain with WMS

Beyond inventory management, WMS plays a significant role in optimizing the entire supply chain. Here’s how:

1. Increased Visibility

WMS provides end-to-end visibility across the supply chain. This transparency allows businesses to track shipments, monitor supplier performance, and predict potential disruptions. With greater visibility, companies can proactively address issues and maintain smooth operations.

For instance, if a shipment is delayed, the business will be able to take corrective actions, such as informing customers about the delay or finding alternative suppliers to mitigate the impact.

2. Cost Reduction

By automating and optimizing warehouse operations, it reduces labor costs, minimizes errors, and decreases waste. Efficient inventory management also lowers holding costs by ensuring stock levels are kept at an optimal level. These cost savings can significantly improve the bottom line.

Automation through WMS means fewer manual tasks and less reliance on a large workforce, directly translating into labor cost savings. Additionally, by reducing errors and waste, the business can avoid the costs associated with returns, corrections, and excess inventory.

3. Better Supplier and Customer Relationships

WMS enables better communication and collaboration with suppliers and customers. With accurate and timely information, businesses can negotiate better terms with suppliers and provide reliable delivery timelines to customers. Enhanced relationships lead to stronger partnerships and increased loyalty.

For suppliers, a business can share inventory levels and forecasts, ensuring timely replenishments and avoiding stockouts. For customers, timely and accurate order fulfillment boosts satisfaction and trust, fostering long-term loyalty.

4. Scalability

As businesses grow, so do their inventory and supply chain complexities. A robust system can scale with your business, handling increased volumes and more complex processes. Scalability ensures that your operations remain efficient and effective, even as your business expands.

Whether expanding to new markets, increasing product lines, or opening additional warehouses, a scalable WMS can adapt to the changing needs of the business, ensuring continuity and efficiency without the need for a complete system overhaul.

Conclusion

Incorporating a Warehouse Management System (WMS) into your inventory management and supply chain operations can transform your business. From real-time tracking and improved accuracy to cost reduction and scalability, the benefits are substantial. By leveraging the power of this system, you can optimize your supply chain, enhance customer satisfaction, and stay ahead of the competition.

If you’re looking to stay competitive in today’s market, it’s time to consider implementing a WMS. The transformation it brings to your inventory management and supply chain processes can be a game-changer for your business.

Investing in a WMS not only streamlines your current operations but also prepares your business for future growth and challenges. Embrace the technology and watch your supply chain evolve into a more efficient, effective, and customer-centric operation.

Ready to transform your inventory management and supply chain? Look no further than 8Stock. Our comprehensive WMS solution is designed to meet the needs of businesses of all sizes. You will benefit from real-time tracking, improved accuracy, and enhanced order fulfillment, all while reducing costs. Request for a demo today and take the first step towards a more efficient future.