Strategies for Reducing Warehouse Operational Costs

Managing a warehouse is a complex task that can be expensive if not handled efficiently. Operational costs can quickly add up, impacting the overall profitability of a business. However, by implementing the right strategies, you can reduce operational costs without compromising on quality or efficiency. Here are some practical strategies to help you reduce warehouse operational costs.

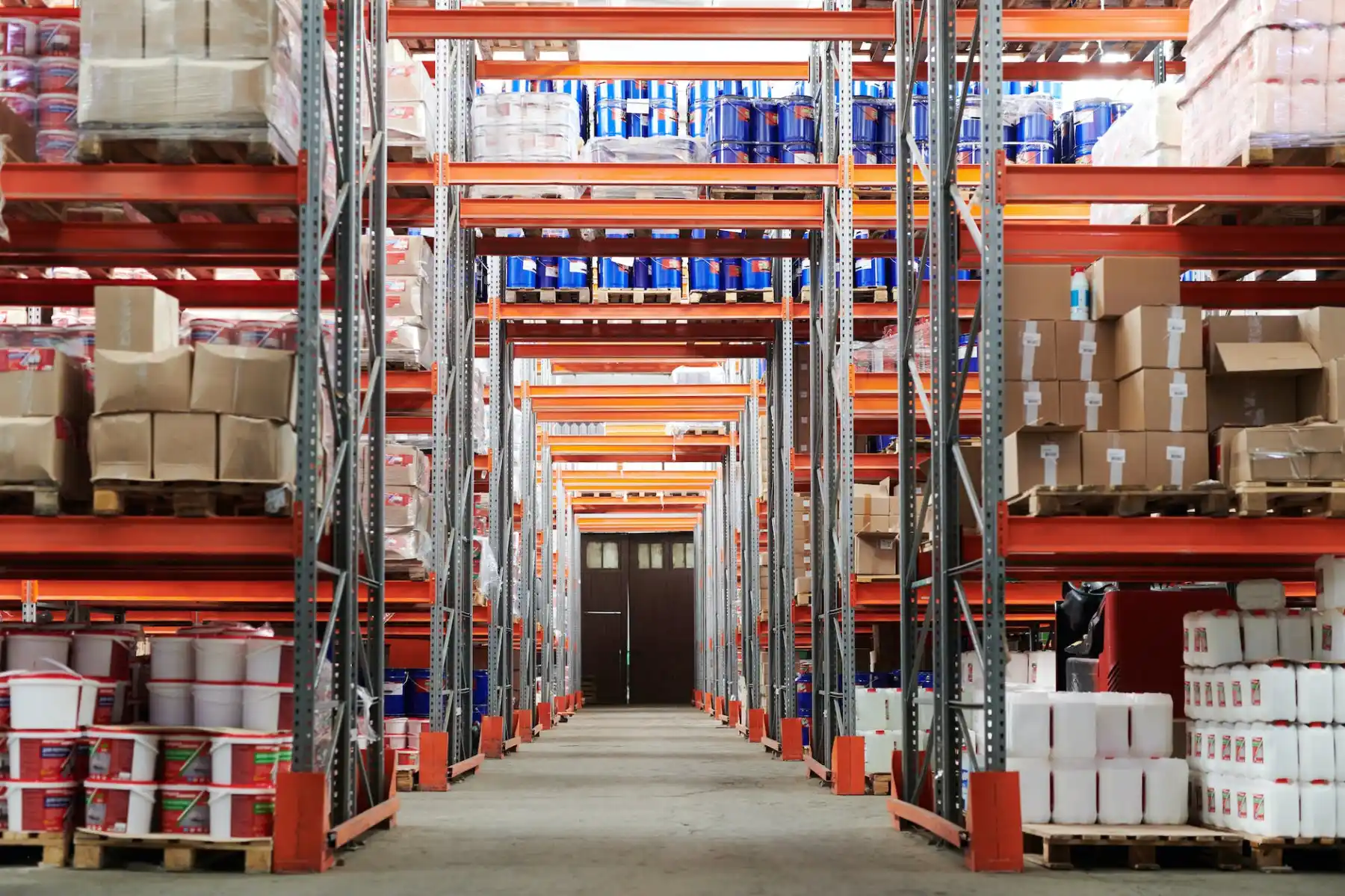

1. Optimize Warehouse Space Utilization

Space is a valuable asset in a warehouse. Poor space management can lead to higher costs, as you may need to rent additional space or manage cluttered environments. One effective way to optimize space is by using vertical storage solutions. This involves using shelves that go higher rather than spreading out horizontally. Additionally, organizing your inventory in a way that maximizes available space can help reduce the need for more square footage.

Another method is to regularly audit your warehouse layout. Ensure that frequently used items are easily accessible and that there’s a logical flow to the placement of goods. This can reduce the time spent on retrieving items, ultimately lowering labor costs.

2. Implement a Warehouse Management System (WMS)

Investing in a Warehouse Management System (WMS) like 8Stock can drastically reduce operational costs. A WMS automates various processes, such as inventory management, order processing, and shipping. By streamlining these tasks, you can reduce human error, lower labor costs, and improve overall efficiency.

A WMS also provides real-time data, allowing you to make informed decisions quickly. This can help in identifying areas where costs can be reduced, such as excess inventory or inefficient workflows. In the long run, a WMS pays for itself by improving operational efficiency and reducing costs.

3. Reduce Energy Consumption in Warehouse to Reduce Operational Costs

Energy costs can be a significant part of your warehouse’s operational expenses. To reduce these costs, consider implementing energy-efficient practices. Start by upgrading to LED lighting, which uses less energy and lasts longer than traditional bulbs. Motion sensors can also be installed to ensure that lights are only on when needed.

Another way to reduce energy consumption is by maintaining your equipment regularly. Well-maintained equipment runs more efficiently and uses less energy. Additionally, consider investing in energy-efficient HVAC systems that can help lower heating and cooling costs.

4. Optimize Labor Efficiency

Labor is often one of the largest expenses in a warehouse. To reduce these costs, it’s essential to optimize labor efficiency. Cross-training employees is one effective strategy. This allows workers to perform multiple roles, reducing the need for specialized staff and enabling more flexible scheduling.

Implementing performance metrics can also help in identifying areas where labor efficiency can be improved. For example, tracking the time it takes to complete specific tasks can highlight inefficiencies and provide opportunities for improvement.

Using a WMS like 8Stock can further enhance labor efficiency by automating routine tasks and providing real-time data for better workforce management. This can lead to a more productive workforce and lower labor costs.

5. Streamline Inventory Management

Excess inventory ties up capital and increases storage costs. On the other hand, insufficient inventory can lead to stockouts and lost sales. Finding the right balance is crucial for reducing operational costs.

Implementing just-in-time (JIT) inventory management is one way to streamline inventory. This approach ensures that you only order and store what you need when you need it, reducing excess inventory and associated costs.

Another effective strategy is to categorize your inventory based on demand. High-demand items should be stored in easily accessible locations, while low-demand items can be stored further away. This reduces the time and effort needed to retrieve high-demand items, ultimately lowering labor costs.

6. Automate Repetitive Tasks

Automation is a powerful tool for reducing warehouse operational costs. By automating repetitive tasks, you can reduce the need for manual labor, lower the risk of human error, and improve overall efficiency.

For example, automated conveyor systems can transport goods within the warehouse, reducing the need for manual handling. Automated picking systems can also speed up the order fulfillment process, allowing you to process more orders in less time.

Investing in a WMS like 8Stock can also help automate various tasks, such as inventory management, order processing, and shipping. This not only reduces labor costs but also improves accuracy and efficiency.

7. Negotiate Better Rates with Suppliers

Another way to reduce operational costs is by negotiating better rates with your suppliers. Building strong relationships with suppliers can give you leverage when negotiating prices. Additionally, consider consolidating your purchases with a few key suppliers to take advantage of bulk discounts.

Regularly review your supplier contracts and compare them with current market rates. This ensures that you’re getting the best deal possible and helps identify opportunities for cost savings.

8. Implement Lean Warehouse Practices

Lean warehouse practices focus on eliminating waste and improving efficiency. By adopting lean principles, you can reduce operational costs while maintaining or even improving service quality.

One key aspect of lean warehousing is the continuous improvement of processes. Regularly review your warehouse operations to identify areas where waste can be reduced, such as excess inventory, unnecessary movement of goods, or inefficient workflows.

Another lean practice is to empower your employees to contribute to process improvements. Encourage them to suggest ways to reduce waste and improve efficiency, as they often have valuable insights from their day-to-day work.

9. Maintain Warehouse Equipment Regularly

Well-maintained equipment runs more efficiently and has a longer lifespan, reducing the need for costly repairs or replacements. Regular maintenance can also prevent unexpected breakdowns that disrupt operations and lead to increased costs.

Implement a preventive maintenance schedule for all your equipment, including forklifts, conveyor systems, and HVAC systems. Regularly check for wear and tear, and address issues promptly to avoid more significant problems down the line.

Investing in high-quality equipment upfront can also save you money in the long run. While it may be tempting to go for the cheapest option, quality equipment is often more reliable and has lower long-term maintenance costs.

10. Use Data to Drive Decisions

Data is a powerful tool for reducing warehouse operational costs. By analyzing data, you can identify trends, pinpoint inefficiencies, and make informed decisions that lead to cost savings.

For example, data on order fulfillment times can help you identify bottlenecks in your process and find ways to improve efficiency. Similarly, inventory data can help you optimize stock levels, reducing the costs associated with excess inventory.

A WMS like 8Stock provides real-time data and analytics, giving you the insights you need to make data-driven decisions. By leveraging data, you can continuously improve your operations and reduce costs.

11. Outsource Non-Core Activities

Outsourcing non-core activities is another effective way to reduce warehouse operational costs. Tasks such as janitorial services, security, and even certain aspects of logistics can be outsourced to specialized providers.

Outsourcing allows you to focus on your core competencies while benefiting from the expertise and efficiency of specialized providers. It can also reduce labor costs, as you won’t need to hire and manage staff for these non-core activities.

When outsourcing, it’s essential to choose reputable providers with a track record of reliability and quality. Regularly review their performance to ensure that you’re getting the best value for your money.

12. Optimize Shipping Processes

Shipping costs can be a significant expense for warehouses, but there are ways to reduce these costs. One strategy is to negotiate better rates with shipping carriers. Many carriers offer discounts for bulk shipping or regular shipments, so take advantage of these opportunities.

Another way to optimize shipping is by consolidating shipments. Combining smaller shipments into larger ones can reduce shipping costs and improve efficiency. Additionally, consider using software that helps you choose the most cost-effective shipping options based on weight, size, and destination.

13. Implement Cross-Docking

Cross-docking is a logistics strategy where incoming goods are directly transferred to outgoing vehicles with minimal or no storage in between. This reduces the need for storage space and minimizes handling costs.

Implementing cross-docking requires careful planning and coordination, but the potential cost savings can be substantial. By reducing storage time, you can also improve the speed of your supply chain, leading to better customer satisfaction.

14. Regularly Review and Improve Processes

Continuous improvement is key to reducing warehouse operational costs. Regularly reviewing your processes allows you to identify inefficiencies and implement changes that lead to cost savings.

Consider conducting regular audits of your warehouse operations to identify areas where improvements can be made. Involve your employees in this process, as they often have valuable insights into where inefficiencies lie.

By continuously improving your processes, you can stay ahead of rising costs and maintain a competitive edge in the market.

Conclusion

Reducing warehouse operational costs is not a one-time effort but an ongoing process. By implementing these strategies, you can create a more efficient and cost-effective warehouse operation. Whether it’s optimizing space utilization, automating tasks, or improving labor efficiency, each of these strategies can contribute to significant cost savings over time.

For businesses looking to take their warehouse management to the next level, investing in a robust Warehouse Management System like 8Stock can be a game-changer. With its comprehensive features and real-time data, 8Stock can help streamline your operations, reduce costs, and improve overall efficiency.

Interested in learning more? To see how it can benefit your warehouse operations.